The Ultimate Guide To Aws Cwi

Table of ContentsEverything about Aws CwiAws Cwi Can Be Fun For AnyoneUnknown Facts About Aws CwiThe Of Aws CwiThe Aws Cwi Ideas

Third-party quality assurance assessment of steel fabrication centers on welding inspection, as well as examination of bolting and painting of architectural steel. KTA's steel assessors supply Quality assurance (QC) examiners to supplement fabricator's/ specialist's internal QC staff and on projects that mandate maintaining the solutions of a qualified assessor (e.g., CWI) used by an independent inspection company.Inspectors conduct visual inspections of product for uniformity with the approved specifications, strategies and codes, along with confirmation of Licensed Material Examination Records (CMTR) for materials utilized. Products and parts are observed at key factors along the production procedure in both steel mills and steel construction stores. KTA's licensed welding assessors additionally witness welder and welding procedure certification tests as relevant to the scope of the job.

Steel construction examination services additionally consistently consist of carrying out non-destructive testing (NDT), likewise understood as non-destructive examination (NDE), including Magnetic Bit Testing (MT), Ultrasonic Testing (UT) and Fluid Penetrant Evaluating (PT). KTA's assessment services include finishing examinations covering surface area preparation, painting, galvanizing, and metalizing.

KTA's approach is to react rapidly to customers' requirements, match the best inspector to the job, and offer the requisite paperwork. KTA has the assistance workers to provide technical consulting to the field workers and to the customer. KTA has specialists offered to get in touch with on welding, NDT and finishings.

Come sign up with a remarkable team in an amazing, fast paced, and ever-growing sector! We are seeking a CWI's and/or NDT Degree II certified Welding Inspectors from in and around the Lithia Springs, GA area!

Aws Cwi for Beginners

Semiconductor, Consumer Products, Bio & Biopharmaceutical, etc. Ideal prospect will certainly have high purity piping examination experience. Present AWS certs are preferred. CWI's and NDT Degree II's extremely encouraged to use.

Pro QC's third-party welding examination solutions consist of: Document Evaluation Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding assessment reports are supplied within 24 hours and document all inspection points appropriate to quality, including all recognized weld blemishes and digital pictures (Certified Welding Inspector) (https://www.brownbook.net/business/53061049/aws-cwi/). Pro QC's team of inspectors delivers third-party welding evaluations around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and much more countries

Inspection of the welding work is vital for proper top quality When your company is taking care of significant projects with demands for third event independent welding assessment, we offer outstanding welding witness inspection solutions to verify that welding has actually been executed according to a lot of used welding standards and specs. AQSS does welding evaluation services for clients from a variety of industries.

Little Known Questions About Aws Cwi.

Not adhering to correctly qualified welding procedures typically causes a weld of poor high quality, which can increase the construction's probability of failure under designated service problems. By inspecting for problems, our examiners can help clients guarantee that their welds satisfy appropriate requirements of quality control (Certified Welding Inspector). Weld inspections are performed for a number of reasons, the most common of which is to identify whether the weld is of appropriate high quality for its desired application

Our welding inspectors have actually the needed accreditations with years of experience with evaluation and are familiar with many used welding criteria and specs. check these guys out AQSS has actually CWI licensed assessors.

The smart Trick of Aws Cwi That Nobody is Discussing

Typically, our inspectors are checking for splits, pits, surface area pores, undercut, underfill, missed joints, and various other aspects of the weld.

Samples can likewise be taken at intervals during the production process or at the end of the run. Destructive screening examples are specifically reduced, machined, ground, and brightened to a mirror-like finish. An acid etch is after that put on visually draw out the weld, and the sample is then checked under a microscope.

Ariana Richards Then & Now!

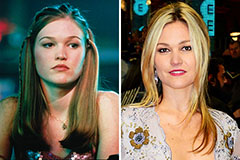

Ariana Richards Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!